INDUSTRIAL HEATERS

Kohli Enterprises is a widely renowned manufacturer & supplier of a rather extensive range of Industrial Heaters such as Tubular Heaters, Cartridge Heaters & High Density Cartridge Heaters, Immersion Heaters, Bobbin Heaters, Band Heaters, Strip Heaters, Finned Strip Heaters, Porcelain Heaters, Open Coil Heaters, Casted Heaters, Infrared Quartz Heaters as well as Heat Tracer Heating Cables which are widely used in numerous industrial heating applications in diverse industries.

We manufacture various types of reliable and highly efficient industrial heaters as per customer's speicific requirements to serve optimally our all numerous industrial clients of India.

- This is a customized item and can be made in any shape and size as per the requirement of customers.

- It is being manufactured in different types of tubes as per the nature of work where it has to be installed like Stainless Steel 304 Grade, Stainless Steel 316, Stainless Steel 310, Incoloy, Inconel, Steel, Titanium etc.

- Fused magnesium oxide powder is used as the insulation material between the tube casing and the resistance heating element.

- We use the best quality of silicon oil for protecting it from moisture and humid environments.

- This is also a customized item and can be made in any size as per the requirement of customers. This is a straight element in which both the terminals of heaters are on the same side in the single tube and the other end of the tube is welded and closed.

- They are used where the temperature is not much and also the wattage is less which makes it more compatible for carrying out a job.

- It requires less maintenance and has a high thermal conductivity.

- This is a customized item and can be made in size as per the requirement of customers.

- These heaters are installed in a liquid component for heating the liquid material. It is being manufactured in different types of tubes as per the nature of liquid in which it has to be immersed.

- Fused magnesium oxide powder is used as the insulation material between the tube casing and the resistance heating element.

- We use the best quality of silicon oil for protecting it from moisture and humid environments.

- There are few types of immersion heaters like Oil Immersion Heaters, Water Immersion Heaters, Flanged Heaters, Circulation Heaters, Inline Heaters & Lead Alkaline Heaters.

- This is a customized item and can be made in size as per the requirement of customers.

- These are ceramic heaters which are used for warming hot air or heating up the fluids as per the requirement. If they are used to heat up a liquid component then this ceramic heater is installed in a metal casing which is further immersed in the liquid.

- They have a high performance rate, moisture resistant and highly durable which increases their shelf life.

- Band Heaters are made for proper contact heating on cylindrical surfaces. These heaters are made in M.S., brass and S.S. sheathing, also made in perforated sheathing for air-cooled application.

- They are two types of band heaters namely Mica Band Heater & Ceramic Band Heater.

- Both types of heaters are covered with insulated jacket to save energy.

- Band heating is an indirect form of industrial heating and offers safety when heating pipes or containers that cannot be heated using direct heating methods.

- Mica Band Heaters are constructed with Mica Sheet wound with heating wire. Further, this wounded sheet is placed in the Metal sheath for outer covering.

- Ceramic band heaters designed with inner resistance coils that are spirally wound. The mat is located beneath a layer of stainless steel giving it high durability and safety environment.

- These kinds of heaters are used for process air heating, surface heating, packaging machines etc.

- These are highly safe in nature and are constructed by using Steel, Stainless Steel, Brass etc. as per the environment where it has to be used.

- Strip heaters can be clamped or bolted onto objects or solid surface contact heating over large areas and are primarily used in indoor applications.

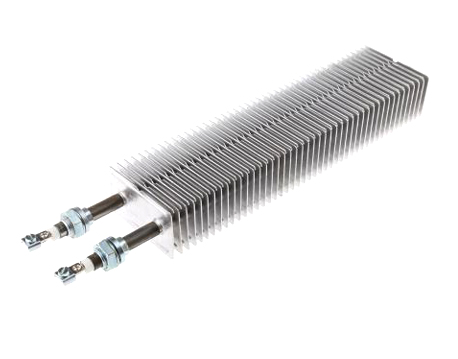

- Finned Strip Heaters are used for maximizing the heat intensity and ensures uniform distribution of heat in the environment.

- Finned strip heaters are composed of a heating element, a protective sleeve or sheath, and mounting hardware along with steel fins that are used to extend surface area.

- Porcelain Heaters are made with high temperature bearing insulators.

- Elements in these heaters are exposed partially in air for better transmission of heat.

- They are mostly used in ovens and tanks where draining is not possible to change the heaters.

- These types of heaters are customized in nature and are constructed as per the requirement for the nature of work to be carried out.

- Open Coil Heaters are designed for high temperature furnaces and offers great efficiency, high reliability and fast heat transfer due to direct expose in air.

- They have a faster heat up time and can be easily replaced when fused.

- Cast Heaters are made by casting iron, aluminium or brass on the tubular heating element.

- Cast heaters are made for high temperature application to heat dies and nozzles.

- They have a longer shelf life as compared to other tubular elements.

- Infrared Heaters are made in ceramic and silica quartz tube sheathing. These heaters are specially designed to use where fast and radiant heating is required.

- These heaters are easy to clean, cost effective and efficient in their respective jobs in process heating.

- They are designed to work for larger areas and every single place that needs radiant heating.

- Many products freeze or become viscous when exposed to ambient temperature. Successful storage and transfer of such products requires the piping and associated equipment to be heat traced.

- It is installed with a temperature controller for self-regulation and it has an excellent thermal stability.